ISTOBAL is digitising the washing of the Riyadh (Saudi Arabia) metro with two pioneering wash facilities that enable the wash process and the maintenance of the equipment to be managed remotely thanks to a communication and connectivity system integrated into the unmanned metros.

The Spanish multinational has developed a customised washing project for the Alstom metro trains on lines 4, 5 and 6, and is the only ancillary equipment provider capable of offering remote maintenance of the wash systems in a way that is integrated into the local Riyadh metro network.

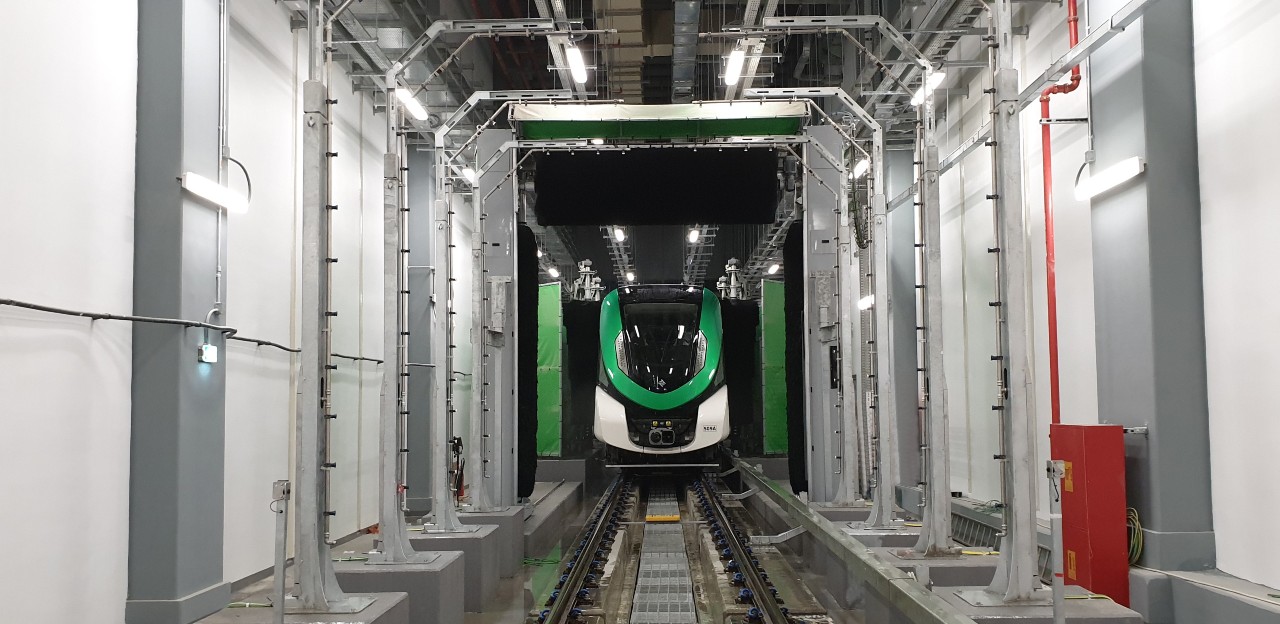

Located at the maintenance terminal of lines 4 and 6 and in the underground maintenance facility of line 5, these wash facilities have a system of automated and standardised ISTOBAL HW'TRAIN THROUGH modules, plant rooms, water recycling system and connectivity system for remote maintenance of the entire facility. They also include a system for connecting and communicating between the wash machines and the metro trains so that the wash process can be synchronised with the automated manoeuvres of the unmanned metros through the metro network's Operational Control Centre. The positioning of sensors in the wash area allows the convoy’s arrival to be detected and the wash to be activated automatically, and the end of the process is communicated so that the metro leaves the facility.

Complete wash in 10 minutes and reuse 75% of the water

The project, which started in 2016 and was completed this year, has a track length of 40 metres consisting of numerous installed modules and arches, as well as an ISTOBAL HW'PROGRESS industrial rollover.

The size of this facility makes it possible to thoroughly wash 72-metre-long convoys in less than 10 minutes. The wash includes washing of the front, rear, side and top of the trains and between wagons – quickly, effectively and sustainably. The facilities also have physical and biological water recycling systems that enable 75% of the water to be reused in each wash and the UV disinfection of the recycled water.

Watch video of the metro wash facilities.

Turnkey solutions for the rail industry

ISTOBAL provides customised comprehensive solutions for the rail industry with technological developments that can be adapted to any facility and that stand out due to their versatility, flexibility, efficiency and reliability. Their project management department covers consulting, design, production of wash equipment, water treatment systems, chemical solutions, as well as installation and maintenance.

Within its line of train and subway wash business, ISTOBAL has developed 43 facilities in 20 countries worldwide that provide an average of 200,000 washes per year. There are currently 10 projects under way in several countries, including Australia, Egypt, France, Hungary and Morocco.